We provide intelligent warehouse management total solutions, focusing on the intelligent management of industrial supplies.

Based on a deep understanding of MRO materials, OEM fasteners, and spare parts,

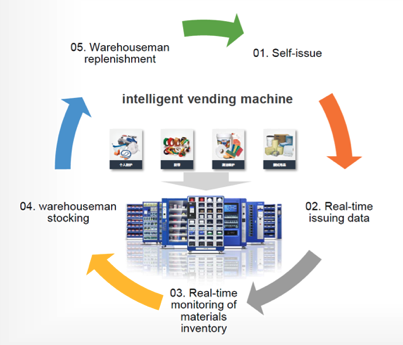

through the production line side deployment of intelligent small warehouse + intelligent management platform.

Using a mature and stable architecture, combined with AIoT technology to intelligent warehousing as the center, to a fully digitalised process of procurement - operations - management.

For enterprises to effectively improve the efficiency of industrial supplies procurement and warehouse management, reduce inventory costs, improve the efficiency of receipt, open up the supply chain upstream and downstream information, accelerate the speed of material turnover, creating more value.

| Common issues in managing MRO activities | KUNTON Vending Machine Solution |

|---|---|

| Difficulty in Tracking & Monitoring | Implementation of Digitalized Monitoring System |

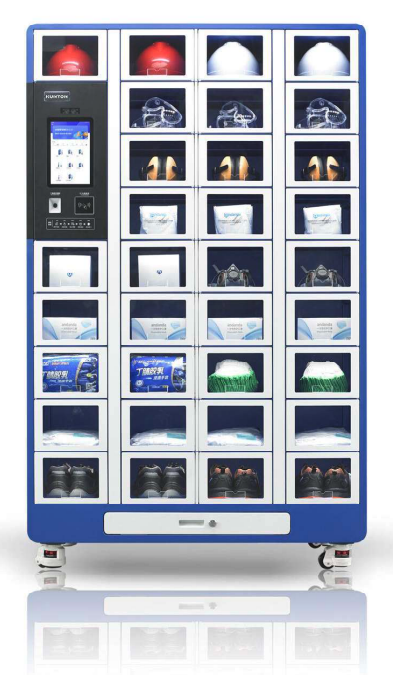

| Delay of delivery from Suppliers | Always-Ready Stock through Vending Machines |

| Extended Downtime due to Delayed Spare Parts | Elimination of Delays with Direct Access To Vending Machine |

| Inefficiencies in Engineering Store Location | Optimal Production Area Placement |

| Complicated Approval Processes and Documentation | Simplified Material Issuing Procedures |

| Limited Accessibility for Night Shift Engineers | Continuous Availability with 24/7 Standby |

| Order Oversight Challenges | System-Driven Stock Alert Mechanism |

| High Inventory Costs | Implementation of Inventory Cost Reduction Measures |

| PPE (Personal Protective Equipment) |  |

| Work Tools |  |

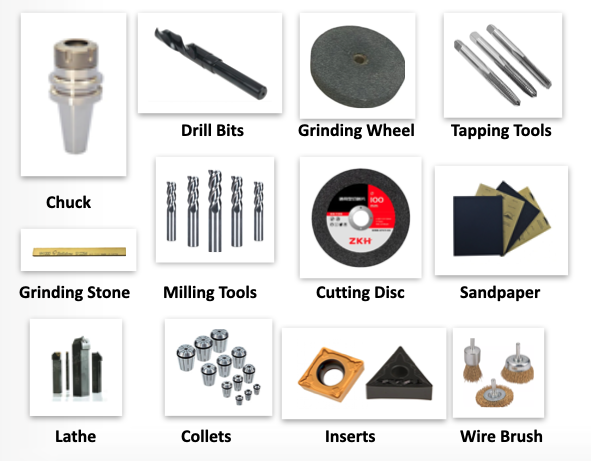

| Abrasive & Cutting Tools |  |

| Transmission Components |  |

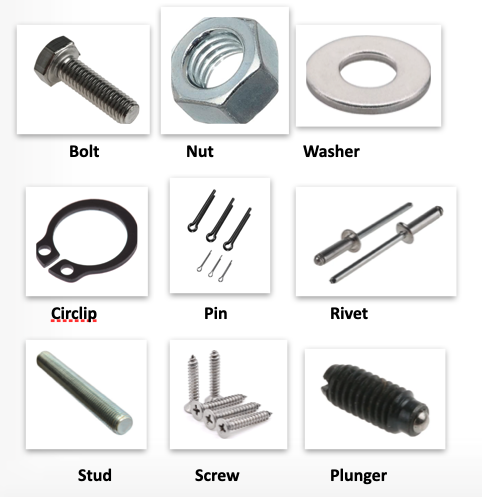

| Fasteners |  |

| Electrical Items |  |

| Pneumatics & Hydraulics Components |  |

| Automation Components |  |

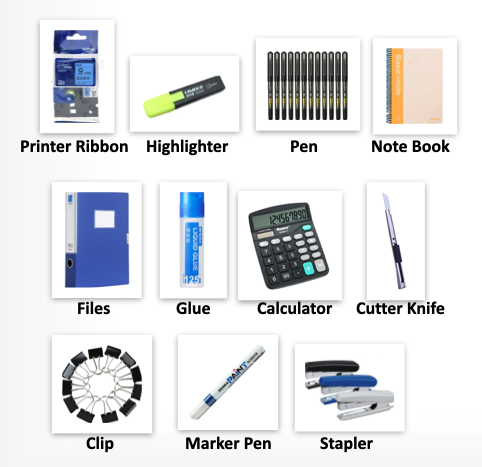

| Administrative Items |  |

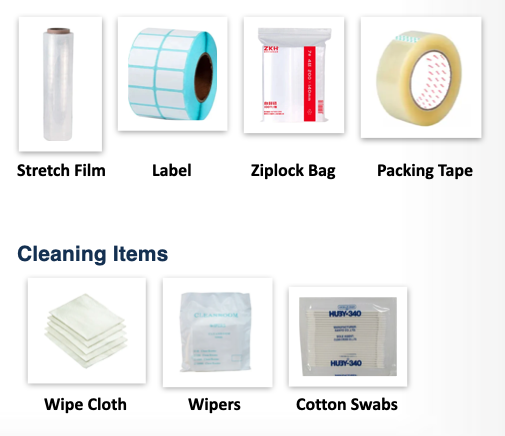

| Packing Items |  |